Overview

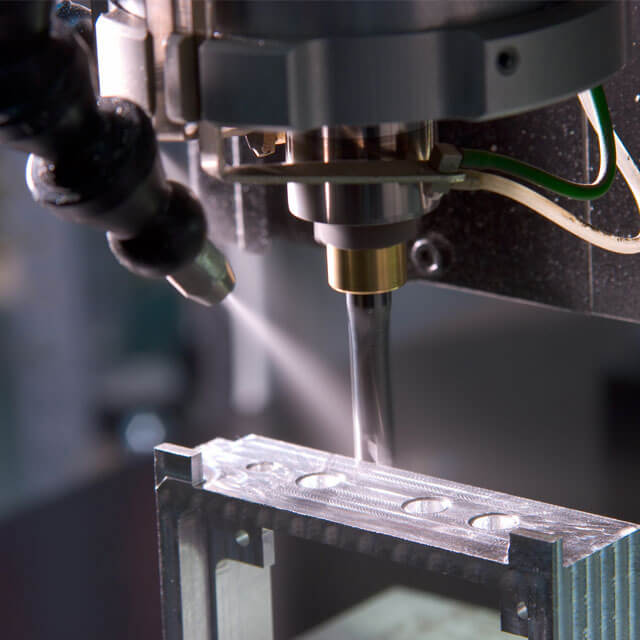

NSK super precision cylindrical roller bearings are designed specifically to handle large radial loads in high-speed spindle applications that require high running accuracy.

Features

- Standard bearings that conform to ISO standards and specialized series for machine tools.

- Double-row cylindrical roller bearings with high rigidity and single-row options for high speeds.

- A range of NSKROBUST™ high-performance bearings for both high rigidity and ultra-high speeds.

Documents

Product List

APTSURF™ Series High-Rigidity Double-Row Cylindrical Roller Bearings

APTSURF™ Series High-Rigidity Double-Row Cylindrical Roller Bearings

New materials in a new design enhance machine tool performance.

Features

- High speeds/low heat generation

An optimized design increases supported speeds and decreases heat generation. - Long life

Grease lubrication extends service life. - Stable rotation

A highly rigid PPS resin cage restricts deformation due to centrifugal force and keeps rotation stable at high speeds.

Standard Series Single-Row Cylindrical Roller Bearings

Standard Series Single-Row Cylindrical Roller Bearings

NSK's standard single-row cylindrical roller bearings conform to ISO standards.

Features

- Long-life materials

NSK's Z steel, a long-life bearing steel, is used as a standard material. - High rigidity

High-rigidity types use a roller-guiding machined brass cage.

NSKROBUST™ Ultra High-Speed Single-Row Cylindrical Roller Bearings

NSKROBUST™ Ultra High-Speed Single-Row Cylindrical Roller Bearings

NSKROBUST bearings feature a highly heat-resistant PEEK cage and heat/wear-resistant SHX steel to achieve a dmN value of 2.2 million.

Features

- Low heat generation

An optimized design achieves low heat generation. - High seizure resistance

SHX steel significantly improves seizure resistance. - Optimized materials for high speeds

Heat-resistant, highly rigid PEEK resin material realizes impressive high-speed performance.

FAQ

- What is the difference between using two single-row APTSURF bearings and using one double-row APTSURF bearing?

-

- Even when the have the same bore/outside diameter dimensions, the internal design and bearing width differ between single- and double-row bearings, so their catalog limiting speeds and load ratings also differ. Because of these variations, be sure to take the dimensions surrounding the bearing into consideration as well.

- What are the differences between the various series (APTSURF, NSKROBUST) of super precision cylindrical roller bearings?

-

- APTSURF bearings are designed for precision machinery at large, while NSKROBUST bearings are specialized for ultra-high-speed applications such as machine tools.

- Be sure that cylindrical oller bearings for the main spindles of machine tools have a suitable amount of grease.

-

- A For cylindical roller bearings for the main spindles of machine tools, we recommend filling 10 to 15% of the free internal space of the bearing with grease. If too much grease is used, abnormal heat generation will occur during the initial stage of operation, causing the grease to deteriorate.