Overview

Nonmagnetic bearings offer higher rigidity and greater resistance to corrosion than conventional stainless steel or beryllium-copper alloys.

Documents

Product List

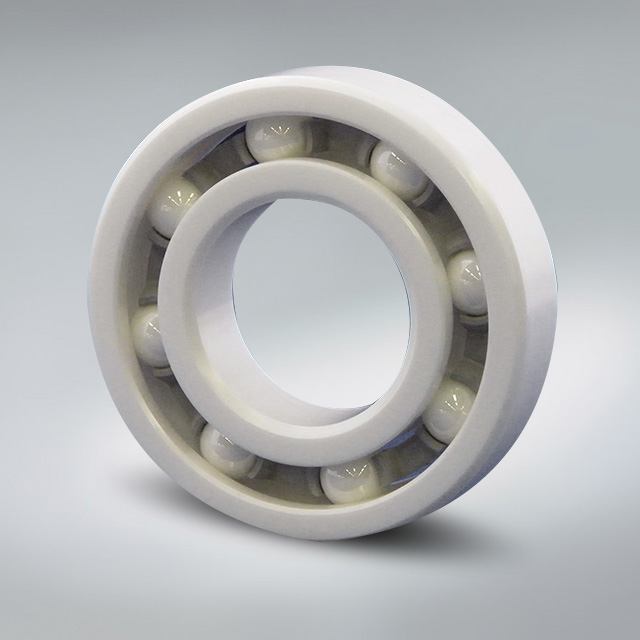

All-Ceramic Bearings (Oxide-Based Ceramic Bearings)

All-Ceramic Bearings (Oxide-Based Ceramic Bearings)

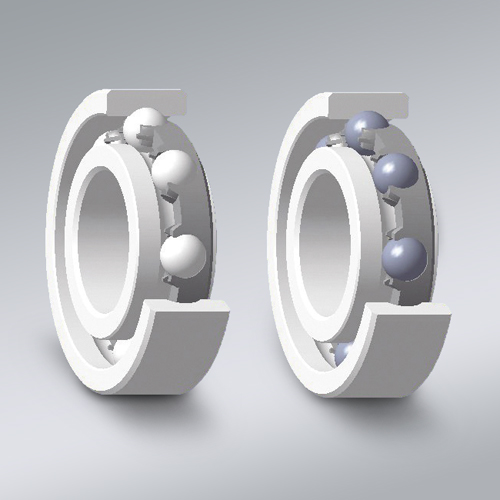

With ceramic outer/inner rings and balls, nonmagnetic all-ceramic bearings have self-lubricating fluororesin cages to achieve excellent resistance to corrosion at both normal atmospheric pressure and in vacuum.

Features

- All-ceramic bearings are fully nonmagnetic.

- They also offer excellent resistance to corrosion and wear.

Applications

- Semiconductor inspection equipment

- Laser inspection equipment

FAQ

- Our plant uses stainless-steel bearings but we found that they attracted/repelled nearby magnets. Are some stainless steels magnetic?

-

- Yes, stainless steels can be magnetic. For example, ferrite stainless steel (SUS440C) will interact with nearby magnets. In contrast, austenite stainless steel (SUS304) has nonmagnetic properties; however it may become slightly magnetic if processing such as cutting or grinding deforms its crystal structure. To ensure that steel is nonmagnetic, you must demagnetize the steel. If this is not possible, we recommend using nonmagnetic all-ceramic bearings as they will always maintain their nonmagnetic properties.

- What is the recommended fit of the shaft and housing for ceramic bearings?

-

- Please use a loose fitting for the shaft and housing.

- How are ceramic bearings lubricated?

-

- Ceramic bearings are not filled with grease. Rather, the cage lubricates the bearing by the solid lubricant within.